Our Services

Big cylinders periodic inspection

Technical inspection is required to maintain containers in proper technical condition and ensure their safe operation. Necessary examinations and inspections are required to identify possible defects, malfunctions, availability and compliance of container markings with requirements of the CSC, the IMDG Code and the Rules for Container Manufacturing.

Tank containers for the transport of dangerous goods should be regularly inspected at least every 5 years 5 years from the date of the initial strength test at the enterprise (manufacturer) with intermediate inspections every 2.5 years.

Cylinder Maintenance

We can help you to hold a routine inspection of cylinders/vessels; this is a necessary step for timely identification of the emergency. An empty cylinder cannot be filled or exchanged for a full one if it’s certification is expired. Like everything else, the cylinder is subject to wear and tear; to avoid accidents, the timely inspection is required.

The cylinders are certified according to a special procedure, which specifies critical values and parameters to identify whether the cylinder is eligible or taken out of service. When the cylinder is inspected, it is marked by the inspecting entity

Helium ISO container periodic inspection

Tank containers intended to carry the dangerous goods shall be subject to regular inspections. This is required to maintain the containers in proper technical condition and ensure their safe operation, as well as to identify possible defects, malfunctions, availability and compliance with all requirements of the container labeling. Our Company will help you to carry out a comprehensive analysis of your tank container, assess the results and perform all works in accordance with the Regulations for the tank container inspection as soon as possible.

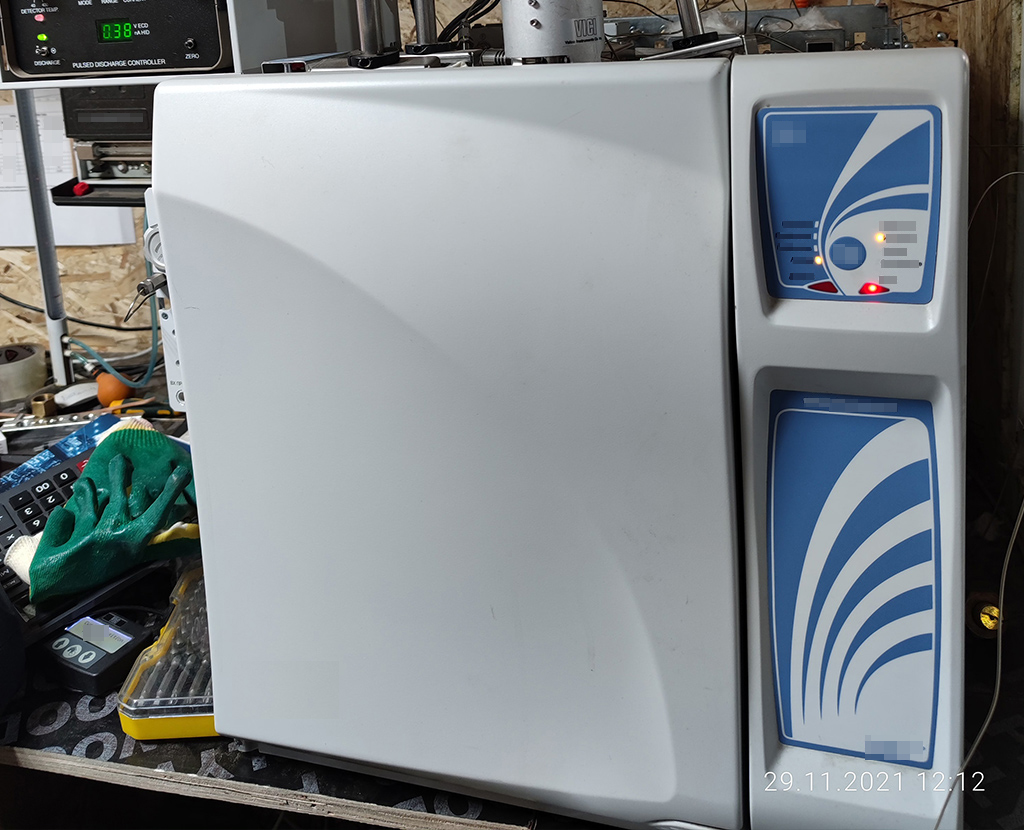

Quality lab

Our laboratory is focused on the quantitative determination of impurities in helium:

Water vapor

Hydrogen

Oxygen

Nitrogen

Methane

Carbon mono- and dioxide

Our equipment also allows the determination of the amount of argon, xenon, and krypton. This is necessary primarily for the correct classification of gases obtained when filling cylinders on the high-purity helium ramp.